Energy Efficiency | November 29, 2021

Sustainability’s In Session at Mitchell College

Located in New London, CT, Mitchell College is a private liberal arts school with a tight-knit community of just over 800 students, faculty and staff. In 2019, the college planned to optimize their HVAC and lighting systems but were unable to fit the efficiency project within their capital plan. Energy conservation was – and remains! – important to the school. Though they wanted to start retrofitting and replacing their aging systems a couple of years ago, the budget of their initial project was originally too high; it needed to be as tight as possible to keep tuition costs down.

Fast forward two years; the state of Connecticut enhanced its utility incentive programs, in part due to the effects of COVID-19. With the support of Mantis Innovation’s turnkey project management, Mitchell College was able to complete a comprehensive lighting and mechanical project with a short payback period and at half the initial cost.

“By choosing to do a comprehensive project and work with [the Efficiency Solutions division of Mantis Innovation], we were able to obtain more incentive dollars than we would have gotten with a smaller project or less experienced company. Being able to complete these projects has resulted in significant sustainability benefits for our campus.”

Joe Pardee, Director of Facilities at Mitchell College

Implementing LED Lighting Solutions

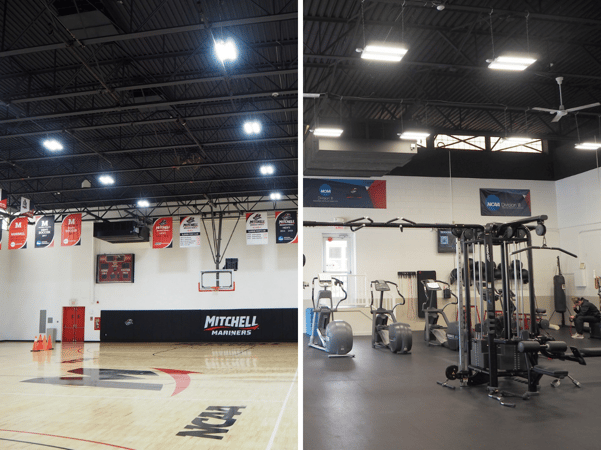

The existing lighting system at Mitchell College consisted of incandescent fixtures that are notorious for being short-lasting and inefficient. They require constant replacement which created a significant maintenance cost for the school as they were frequently purchasing new lighting fixtures and spending time replacing old ones. To combat this challenge, we replaced the existing fixtures with LEDs which require 70% less energy consumption and typically have a rated life of well over 50,000 hours. This was critical for a school with multiple classrooms, resource centers, and student housing.

As installations can be disruptive to the routine of faculty and students, our lighting team needed to be especially cognizant of scheduling. This required frequent and effective communication with faculty to work around classes to best mitigate the disturbance to the students. In addition, the Mantis lighting team was navigating the installation partly during the COVID-19 pandemic, necessitating even closer communication with the school to maintain the safety of everybody involved.

Environmental Equivalent of the Lighting Solutions

845,500 total annual kWh saved at Mitchell College is the environmental equivalent of:

- 734 acres of U.S. forests sequestered in one year

- Carbon sequestered by 109 homes’ electricity use for one year

- Greenhouse gas emissions avoided by 25,495 trash bags of waste recycled instead of landfilled

Replacing Inefficient Boilers

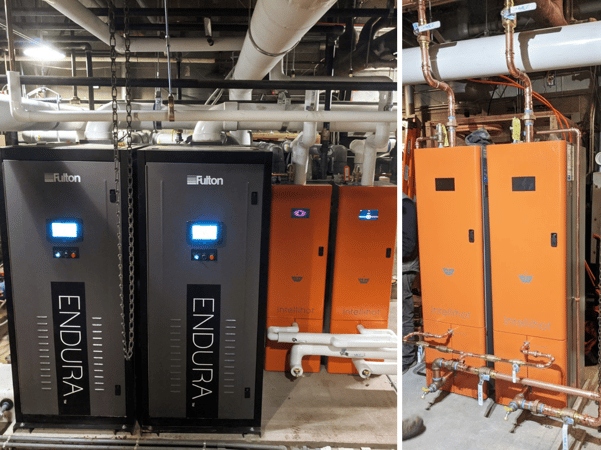

Located in the Clarke Center on campus, the mechanical room originally hosted two large oil-fired boilers. The larger boiler was mainly used during the winter season for both domestic hot water and heating. The smaller of the two was used all year for hot water on campus. The staff at Mitchell College encountered similar problems with these boilers to the lighting; they needed frequent maintenance and produced high carbon emissions.

To solve this problem, we sustainably disposed of both boilers and replaced them with two gas-fired condensing boilers and two gas-fired water heaters. So now instead of two big pieces of machinery, four much more efficient units sit in the mechanical room and take up less than half the space. For the sake of the staff’s convenience, we programmed the boilers and heaters to connect to the building management system.

Redundancy is Necessary for Smooth Operations

Having two units for each job allowed for redundancy as failure of one of the units will not cause major issues. For example, if the existing boiler – that was previously used year-round – failed, the kitchen would not have access to hot water which would be problematic as it serves as the main food source for students on campus.

Redundancy also allows for the equipment to share the task and mitigate exertion. I like to use the running shoes example: If you’re an avid runner, you own two pairs of running shoes and alternate between them. By doing this, both of your shoes will last longer. We applied the same theory to these HVAC systems. By having two units alternate in exertion, they will last much longer.

Finally, we equipped the four rooftop units with an enhanced control system and variable frequency drives (VFD). This system allows for changes in fan speed based on mode of RTU operation (refrigeration stage 1, refrigeration stage 2, ventilation, heating).

One challenge my team faced during this project was turnaround time. Our work was done during the colder months (heating season) when the boilers and heaters would be in high use. This meant the removal of existing equipment and installation of new machinery had to be executed as fast as possible.

Environmental Equivalent of the HVAC Solutions

4,200 total annual therms saved in this HVAC project at Mitchell College is the environmental equivalent of:

- CO2 emissions from 24,562 pounds of coal burned

- Carbon sequestered by 27.2 acres of U.S forests in one year

- Greenhouse gas emissions avoided by 946 trash bags of waste recycled instead of landfilled

The Financial Savings of a Comprehensive Energy Efficiency Project

The results of this project will save Mitchell College around $187,000 annually. The Efficiency Solutions division at Mantis was able to deliver a comprehensive project with three separate savings measures which equate to better savings all around. Comprehensive projects translate to high incentive dollars; for this school, it meant $643,000 in utility incentives.

By taking advantage of the state’s utility incentive project, they were now able to retrofit their lighting to increase efficiency and add controls as well as improve the infrastructure on campus by implementing new boilers and heaters. All of these upgrades were completed with 60% of the cost covered. And now, the efficiency benefits and sustainability outcomes of the project will benefit staff and students for years to come.

Related Posts

Discover more content and insights from Mantis Innovation

The Cost of Inaction: Why Businesses Should Act Now on Energy Efficiency

In today's fast-paced business environment, the financial and operational losses businesses incur by delaying energy efficiency improvements, the "cost of inaction," is more relevant than ever.

In today’s AI era, human intelligence is the key to data center facility and energy optimization

Nowhere else in modern industry do artificial and human intelligence converge with such transformative potential as in the world of data centers. As AI's extraordinary growth accelerates demand for

Your Guide to LED Lighting for Business and Commercial Buildings

Never to be underestimated, LED lighting and well-designed lighting retrofits and upgrades offer businesses big improvements like reduced energy costs, reduced emissions, and improved working

Five Trends Driving Data Center Facility Energy Optimization

Today’s digital economy, commercial and industrial digitalization, and the recent explosion in artificial intelligence and machine learning (AI/ML) powered computing are driving massive growth in