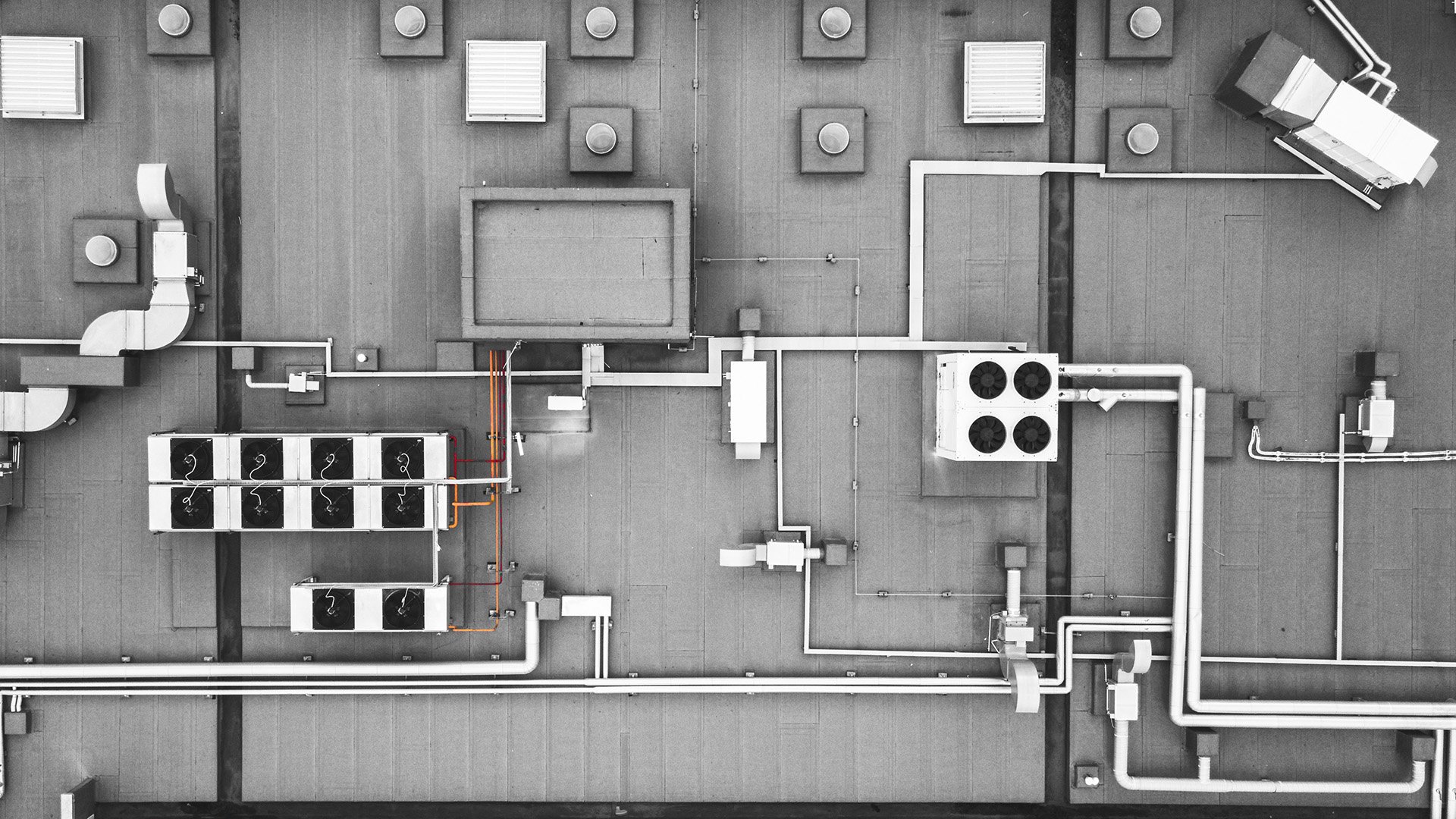

HVAC mechanical | October 31, 2018

The Mechanics of Mechanical Engineering

We sat down with James Taxiera, Senior Mechanical Engineer at Mantis Innovation, to discuss his background and thoughts on current trends for mechanical upgrades.

Can You Tell Us a Little About Your Background?

I graduated from the Massachusetts Maritime Academy with a degree in Facilities and Environmental Engineering. Prior to joining Mantis Innovation, I held multiple positions including working as a Field Engineer in the power generation field, as a commissioning engineer in the biomedical/pharmaceutical industry, and most recently as a representative for an HVAC manufacturer.

What are some of the current trends you’re seeing when it comes to mechanical systems?

There are multiple trends in mechanical systems in the commercial HVAC market. One of the most prevalent is hydronic and domestic-water systems in commercial applications. As new technology becomes available, mechanical engineers scrutinize the design and implementation of these systems to increase energy efficiency and system performance which, in turn, prolongs the life of the equipment.

One way to achieve higher efficiency and overall performance is with variable-speed pumping. Using variable-frequency drives (VFDs) on constant speed pumps and fans drastically improves performance and energy efficiency on commercial heating and cooling systems, as well as domestic hot water systems. VFDs, along with onboard technology, allows for real time control and operation. No longer is a system pumping at a single setpoint and sensor, but now the pump is operating based off system requirements, i.e., system differential pressure, temperature, or flow. This results in a true matching of the load to operation based on the requirements of the system.

Can a company expect limited interruption in their operations when going through a mechanical upgrade?

Depending on the type of facility getting the upgrade, it is possible to limit interruption to operations by proper scheduling. When scheduling around a facility’s peak operation time, it is possible to stage/pre-install the equipment, then tie into the system once it has been fully commissioned. This keeps downtime to a minimum.

There are options for facilities when it is not possible to interrupt operations, such as mission critical (data centers) or health care facilities (hospitals). Most of these facilities have redundant (n+1) equipment; in case of failure they can easily switch to this backup system. This backup enables a facility to ensure mechanical upgrade will not impact operations. When a facility does have backup or redundant equipment, mobile systems, such as trailers, enable upgrades and uninterrupted service. These self-contained trailers can be outfitted with boiler (hydronic and steam), chilled water, and domestic-hot water systems. They can be brought directly to site and tied into the existing system for emergency operation or planned retrofit or replacement of down or failed equipment. These work for both single story sites and high-rise buildings.

What industries do you see as good prospects for mechanical upgrades to save money and receive significant incentives?

Quite a few industries benefit from mechanical upgrades that save money and provide significant incentives. The hospitality market is one – hotels typically operate 24/7/365 with very limited planned shutdowns, if any.

The Domestic Hot Water system is one of the largest consistent energy users in a hotel. In the past, most of these systems were over-designed and much larger than necessary. There are many reasons behind this, but as one plumbing design engineer once told me “I never get a call because we have too much hot water, I get a call when we don’t have enough.” Also, the incentives and guidelines to design around a tight system (meaning properly sized) were not as stringent.

Most older DHW systems were storage type systems that incorporated large (sometimes multiple) storage tanks and pumps that needed to maintain a certain temperature and avoid stagnation to inhibit the presence of legionella bacteria in the system. Although there are still instances where storage-type systems are necessary, they’re becoming few and far between.

Over the past 5-10 years technology for commercial water heaters has moved to more of an on-demand and semi instantaneous design. These designs both have a much smaller footprint, and are highly incentivized. Using this type of hot water system can cut capital and operational costs dramatically as compared to a traditional tank system.

Related Posts

Discover more content and insights from Mantis Innovation

Importance of Updating HVAC in Pharma + Biotech

The ability to control and automate building systems, including HVAC, is an obvious gain for a facility manager. HVAC systems are critical to any facility's purpose and are responsible for several

The Rising Popularity of Heat Pumps and the Challenges of Commercial Retrofits

Heat pumps are becoming increasingly popular across many parts of the U.S., thanks to their energy efficiency and reduced greenhouse gas emissions compared to other building heating and cooling

6 Reasons You Need HVAC Asset Management Right Now

Keeping tabs on your HVAC assets can be a real pain. With different systems, manufacturers, install dates, and repair priorities, it’s a lot of data to track. If you manage a large portfolio of

3 Common Concerns for Your HVAC Units Going Into Spring

3 Common Concerns for Your HVAC Units Going into Spring HVAC systems regulate and move heated and cooled air throughout residential and commercial buildings, from homes, to offices, to indoor