Energy Efficiency | September 24, 2020

Energy Consumption by Sector [Charts and Data Points]

Breaking down energy use by industry can also help identify the potential for energy efficiency in that sector as well. Commercial/industrial companies can figure out where to concentrate time and resources on efficiency tactics based on building type. Because industries have specific points of focus – the importance of refrigeration in the grocery sector, for example – individual companies have differing energy priorities. The US Energy Information Administration (EIA) shares that “U.S. energy expenditures increased by nearly $200 billion from 2016 to 2018, a 17% increase in real terms, as both energy consumption and average energy prices increased faster than population and gross domestic product (GDP) in the United States.” Over the last 10 years, efficiency tactics have decreased energy usage for individual companies but processes across industries continue to demand a high amount of power.

Energy use in commercial buildings

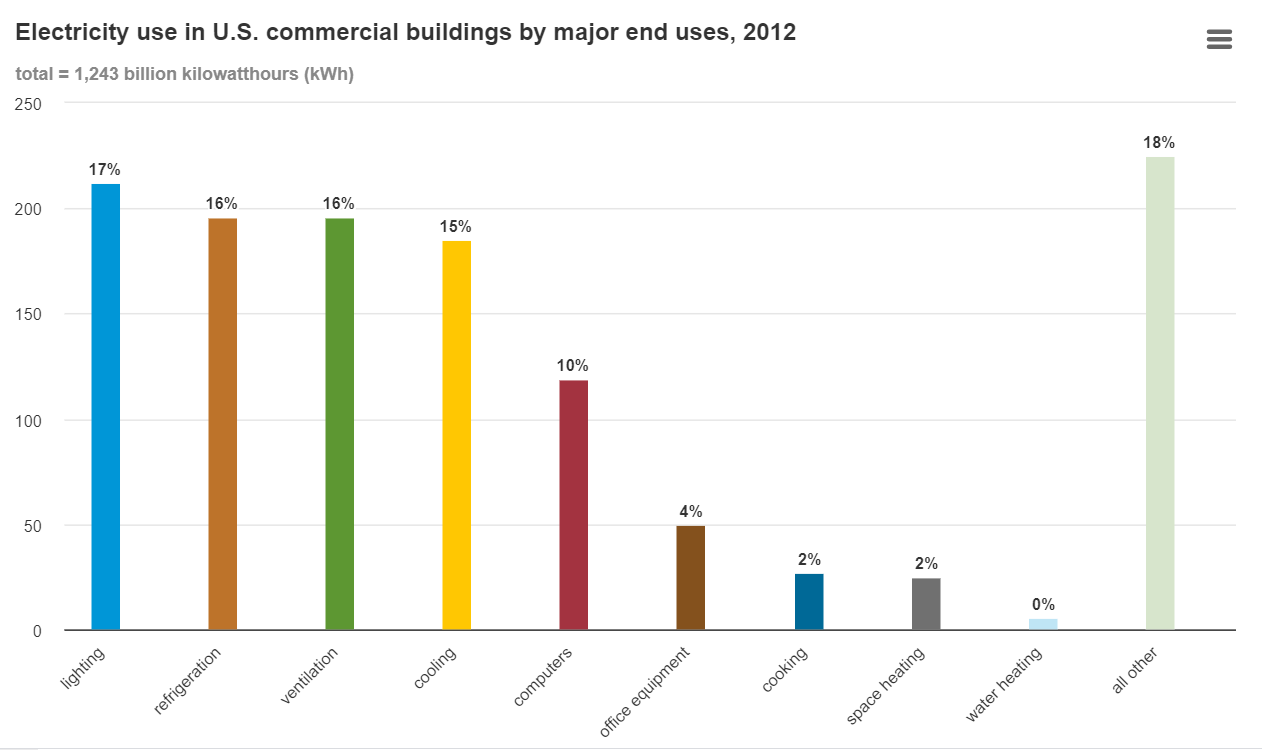

Most large commercial/industrial buildings use 15-20% of their energy use on lighting and 35-50% on HVAC. The EIA will be releasing their latest data (gathering from 2018) in the coming months. Until then, these 2012 charts are our current, accurate reflection of energy use in commercial buildings.

Image source: EIA.gov

Averaging across sectors, this chart’s top four items are no surprise. While lighting may feel like a less significant part of many buildings’ energy bills, the reality is that this consumer of energy provides an efficiency tactic for most commercial energy users.

Energy consumption by sector

Breaking down energy use by industry narrows down where – and why – certain industries struggle to manage energy use. The following sectors use energy very differently, depending on the needs of the businesses, but for each one energy management and increased energy efficiency are crucial.

1. Biotech

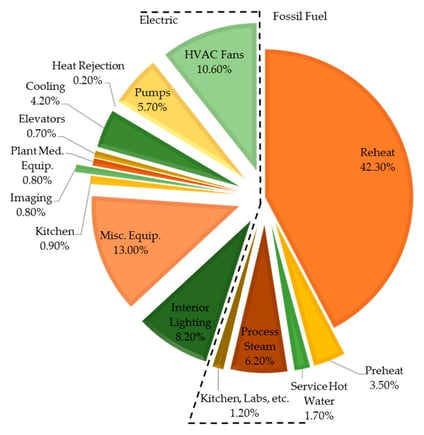

Energy consumption in the biotech and pharma industries is rooted in HVAC. Mechanical systems must support a large number of processes critical – and often unique – to biotech.

Pharmaceutical Engineering published in 2013, “This problem is exacerbated in the pharmaceutical industry due to the need to maintain critical environments for production with respect to temperature, humidity, room pressurization, cleanliness, containment, and other contributing factors.”

Our post on energy efficiency in biotech and pharma explains, “65% of the energy is used by HVAC systems, 25% used by plug loads and processes (such as microscopes, incubators, or sterilizers), and 10% of energy is consumed with lighting the facilities.” Biotech and pharma are a top industry that can benefit from decreasing energy consumption through efficiency solutions.

2. Data centers

Historically, data centers have been one of the largest users of energy in the world. Today’s total energy use by data centers, worldwide, accounts for about 1%. Overall data center energy use grew about 6% between 2010-2018, a slower growth rate than researchers previously estimated due to improvements in equipment, design and product efficiency. During the same period of time, global data center storage capacity increased by a factor of 25.

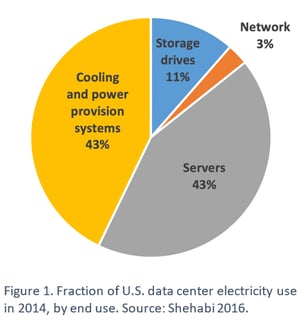

Data center electricity consumption is broken out to 50% used by equipment and 25-40% by HVAC and power/cooling systems. Power and cooling are critical to maintaining computer room environment temperature levels and powering CRAC units. The remainder of a data center’s energy use may be consumed by other building needs.

Image source: EnergyInnovation.org

3. Education

Energy use for educational facilities is of greatest concern to large, university campuses. However, K-12 and independent institutions or private high schools can also benefit from lowering energy use. Schools and educational facilities are high energy users based on the variety of buildings they power.

EnergyStar reports that our 17,000 K-12 US schools spend over $6 Billion on energy annually. Up to 30% of school energy use is managed inefficiently.

Any school that spends a high portion of their operational budget on energy should certainly consider where energy consumption can be cut – both for annual energy savings and lessening impact on the environment, while simultaneously decreasing costs.

4. Grocery & Retail

For grocery and retail, energy consumption is an important consideration because profit margins tend to be proportionate to energy spend.

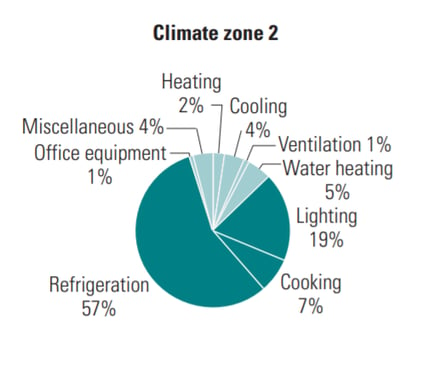

One of the highest energy expenditures tends to be lighting, as well as refrigeration. According to National Grid, “In a typical grocery, refrigeration and lighting represent between 44 and 77 percent of total use depending on climate.”

Lighting for these large spaces and constant refrigeration for produce and food products in grocery stores requires a lot of consistent energy usage that adds up over time. As Energy Star reported, “On average, supermarkets in the United States use around 50 kilowatt-hours (kWh) of electricity and 50 cubic feet of natural gas per square foot per year.” When multiplied by square foot over the course of a year, 50 kWh can quickly add up to high energy use and an expensive utility bill for supermarkets.

Furthermore, the commercial demands of grocery and retail require specific temperature and lighting requirements, usually resulting in high energy utilization, in order to appeal to customers and properly present product offerings.

Image source: National Grid

Climate zone 2 = New England, parts of the Midwest including Pennsylvania, Ohio, Indiana and Illinois, Nebraska, and some stretches of Nevada and Oregon.

5. Healthcare

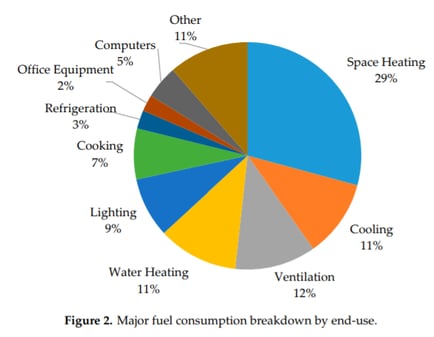

Healthcare is a very energy dense industry, and most of this energy expenditure — over 63%— goes toward HVAC systems, due to ventilation requirements and the size of the facilities. Large hospitals, in particular, understandably consume the largest proportion of energy use. “Large hospitals, constituting 47% of the total area in healthcare facilities, are responsible for 64% of total energy consumption in this sector,” MDPI reports.

Healthcare facilities are particular with their energy usage because many have been built up, out and expanded over the course of several decades. This results in many different systems, some very outdated, that complicate energy usage in the industry. Furthermore, many factors relating to healthcare, like 24-hour runtimes and high-energy equipment make the industry so energy dense.

Image source: fairbanksenergy.com

Image source: MDPI.com

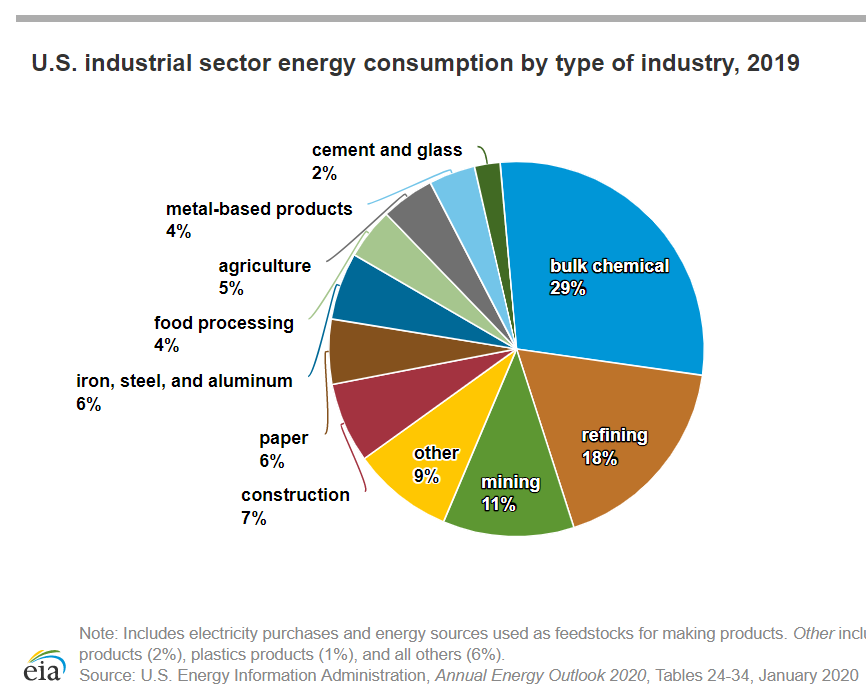

6. Manufacturing

Certain types of manufacturers will face higher energy demands than others:

Image source: EIA.gov

This chart shows that different processes will have higher energy consumption (bulk chemical being the highest user), on top of the standard lighting and HVAC requirements of manufacturing plants.

Manufacturing facilities are often great candidates for efficiency projects because of facility square footage as well. Large buildings coupled with energy intensive processes mean there’s high energy consumption and corresponding potential for efficiency improvements.

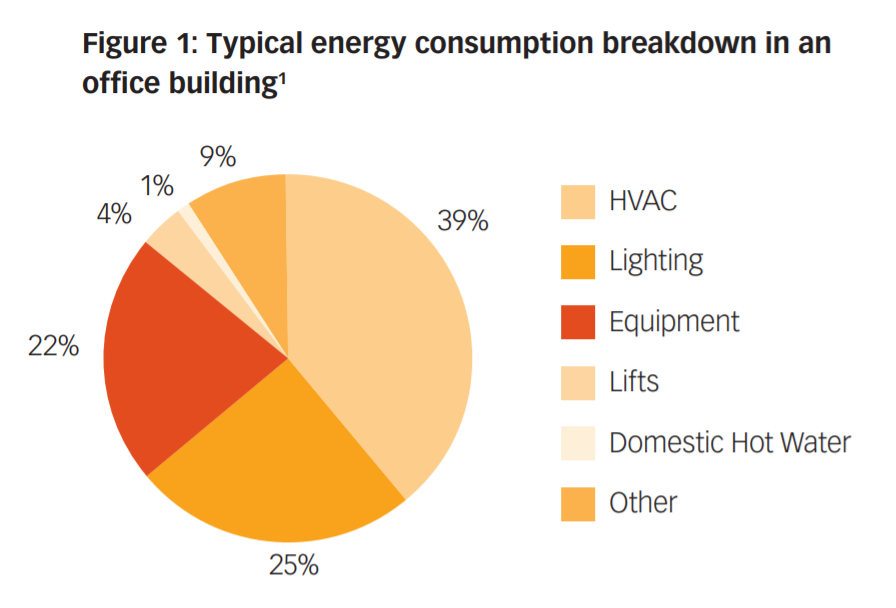

7. Property Management

Energy consumption in the property management industry typically means the energy used by buildings managed by a third party. On the commercial real estate side, these are usually office buildings or corporate campuses. HVAC represents a solid 39% of overall energy use for a typical office building. Lowering this portion of a utility bill can results in significant annual financial savings for the building.

In addition, property managers can increase the value of their properties by implementing energy savings measures.

Image source: Environment.gov.au

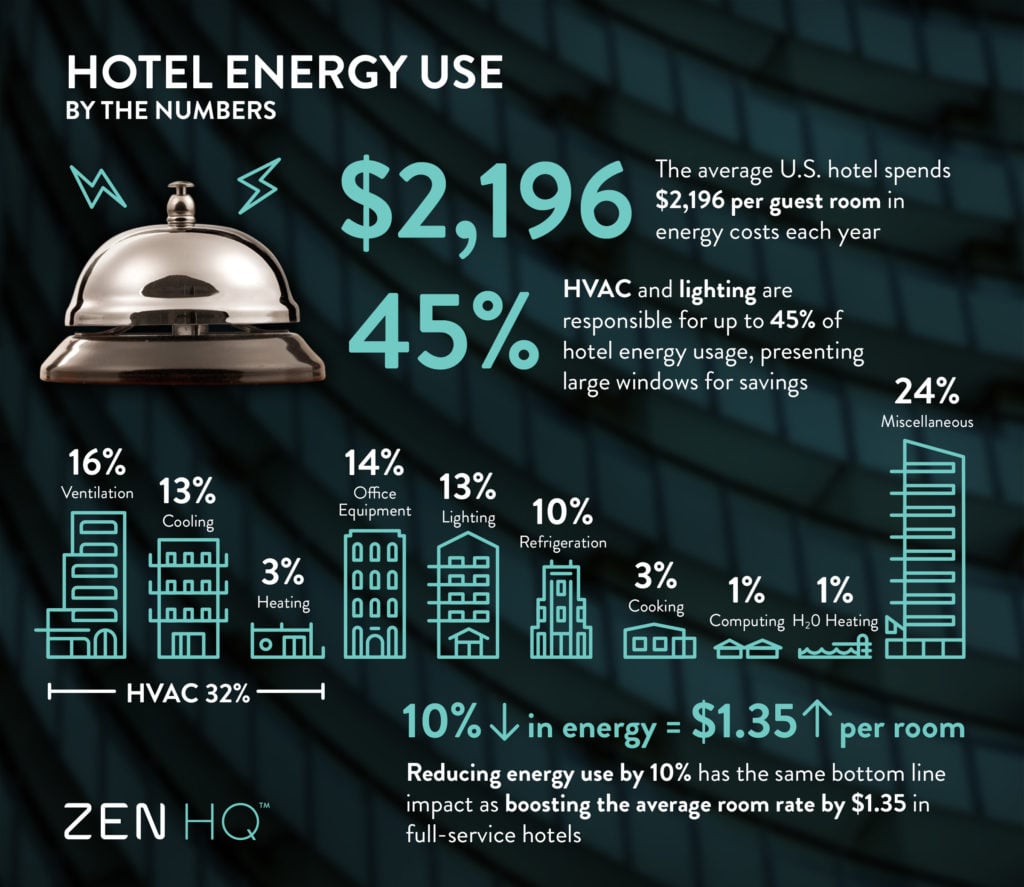

8. Recreational & Hospitality

Hotels are a great example of businesses in the recreational and hospitality industries that face high energy intensity requirements. Where other industries’ power breakdown falls closer to 40% on HVAC and 18% on lighting, hotels use about 32% of their overall energy expenditure on HVAC and 13% on lighting. Other miscellaneous power demands (pools, gyms, conference areas, meeting rooms, etc.) take more overall power than other industries.

On average, US hotels spend $2,196 on energy costs per room every year. Solutions like LED lighting or building management systems that tie room temperature to property management systems can decrease this average cost per room, resulting in significant financial savings.

In addition, the sustainability benefits of lowered energy consumption are becoming more important to hotel brands and their guests.

Image source: Lodging Magazine

Efficiency retrofits result in benefits for all – no matter the industry

While energy management may look very different for each sector, due to the sectors’ use needs, each sector stands to benefit from increased energy efficiency. Through an energy efficiency project, different sectors see real effects on profit, increased efficacy, lower maintenance costs and better building environments, all key factors when looking at your energy utilization. The first step to knowing how to improve your energy efficiency remains knowing what energy management and energy needs are unique to your industry.

Related Posts

Discover more content and insights from Mantis Innovation

The Cost of Inaction: Why Businesses Should Act Now on Energy Efficiency

In today's fast-paced business environment, the financial and operational losses businesses incur by delaying energy efficiency improvements, the "cost of inaction," is more relevant than ever.

In today’s AI era, human intelligence is the key to data center facility and energy optimization

Nowhere else in modern industry do artificial and human intelligence converge with such transformative potential as in the world of data centers. As AI's extraordinary growth accelerates demand for

Your Guide to LED Lighting for Business and Commercial Buildings

Never to be underestimated, LED lighting and well-designed lighting retrofits and upgrades offer businesses big improvements like reduced energy costs, reduced emissions, and improved working

Five Trends Driving Data Center Facility Energy Optimization

Today’s digital economy, commercial and industrial digitalization, and the recent explosion in artificial intelligence and machine learning (AI/ML) powered computing are driving massive growth in